Imperial 3D Printer: Additive Manufacturing of Large Parts in Space Missions

2 min. read

Updated on

Read our disclosure page to find out how can you help MSPoweruser sustain the editorial team Read more

Additive manufacturing or 3D printing is an essential need for astronauts in space. It helps the team to manufacture on-demand structures, tools, and spare parts they need to keep the space station in good condition. This will allows sustainable maintenance of the place while preventing the launching of long-duration deep space missions from the earth that can be costly. Despite these advantages, however, there are still some restrictions about 3D printers – limited printing volume. This is what Project Imperial tries to solve.

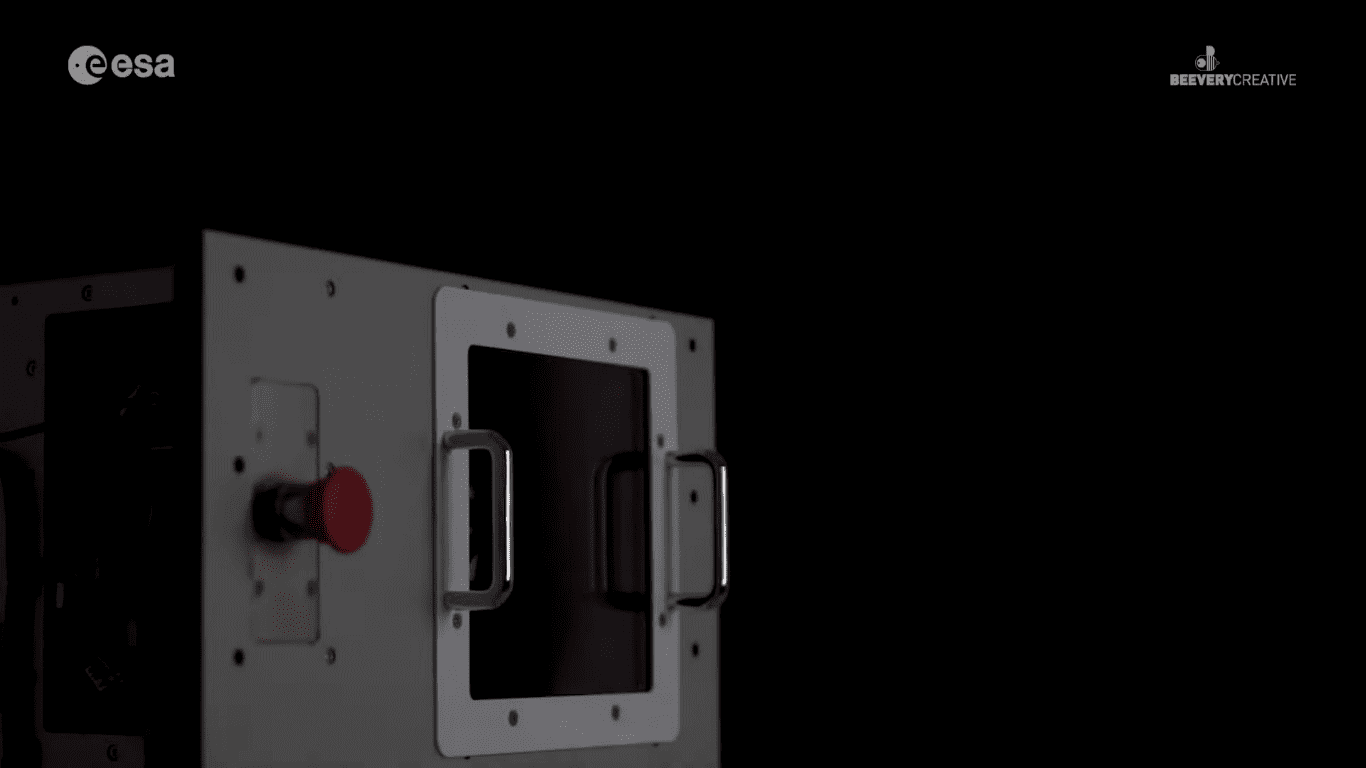

The Imperial 3D printer is the solution to the need of the European Space Agency that has been looking for ways to bump up the ability of 3D printers. Designed by a Europe-wide industrial consortium led by OHB in Germany, alongside the Azimut Space in Germany, BEEVERYCREATIVE in Portugal, and Athlone Institute of Technology in the Republic of Ireland, the Imperial 3D printer goes beyond the capacity of conventional 3D printers you see in the market. It can produce polymer parts of unlimited size along one dimension. This means it can print large parts bigger than the printer itself, allowing astronauts to easily 3D print large parts vital to the autonomy and sustainability of future space missions. The high-performance polymers products it can print are also said to have robust mechanical properties to ensure they can serve their purpose efficiently.

Moreover, the Imperial 3D printer is literally made for out-of-earth additive manufacturing. Apart from being compatible with the Columbus module of the International Space Station, it is independent of gravity, making it possible to print materials in any position without problems. And now that it is complete and ready to be used, it is set to be tested in space aboard the International Space Station.