Battery pioneer to take on Tesla's Powerwall with 90% cheaper All-Polymer Battery

Stationary batteries are set to be a $100 billion by 2025 , and new battery start-up All Polymer Battery is getting ready to take a chunk out of that market with the eponymously named technology, an all-polymer battery.

Invented by Hideaki Horie, who pioneered the Nissan Leaf, the best-selling EV for a decade, while working at Nissan, the technology promises to be 90% cheaper than standard batteries.

“The problem with making lithium batteries now is that it’s device manufacturing like semiconductors,” Horie said in an interview. “Our goal is to make it more like steel production.”

Horie says his process is more akin to making a sandwich than the moisture-controlled clean rooms required to make standard Lithium-ion batteries.

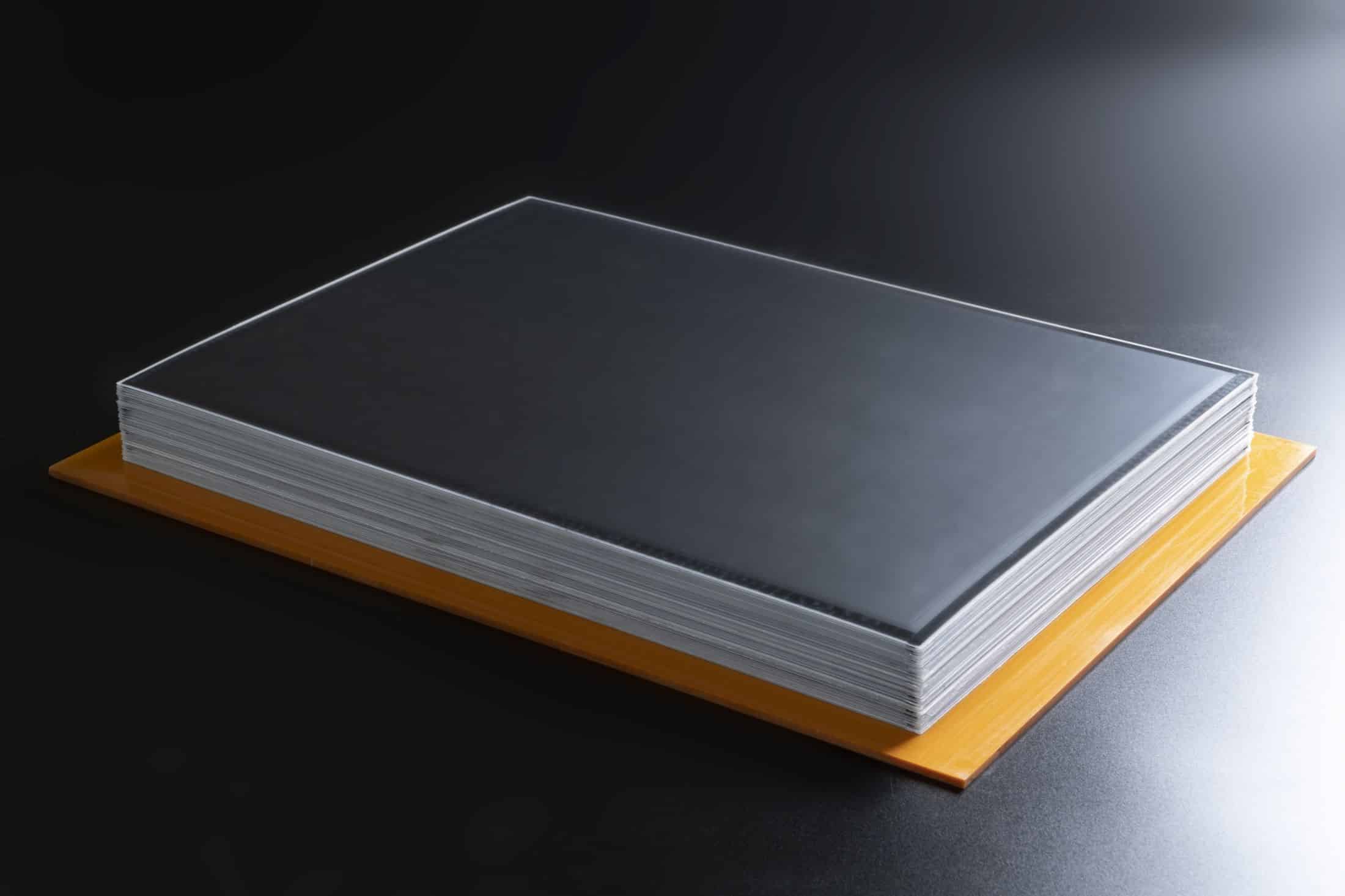

His resin-based battery process allows for 10-meter-long battery sheets that can be stacked on top of each other “like seat cushions” to increase capacity, he said.

The main drawback of the technology is energy density, which is why APB is concentrating on the stationary market in buildings, offices and power plants first.

Horie has teamed with Sanyo Chemical Industries Ltd., to develop the world’s first battery using a conductive gel polymer and already have their first customer lined up, a large Japanese company whose niche and high-value-added products sell mostly overseas.

The company has also raised 8 billion yen ($74 million) to fully equip one factory for mass production slated to start next year with plans to expand to 1 gigawatt-hour capacity by 2023.

“This will be the proof that our batteries can be mass-produced,” Horie said. “Battery makers have become assemblers. We are putting chemistry back into the lead role.”

Read more about the technology at JapanTimes here.

Read our disclosure page to find out how can you help MSPoweruser sustain the editorial team Read more

User forum

0 messages